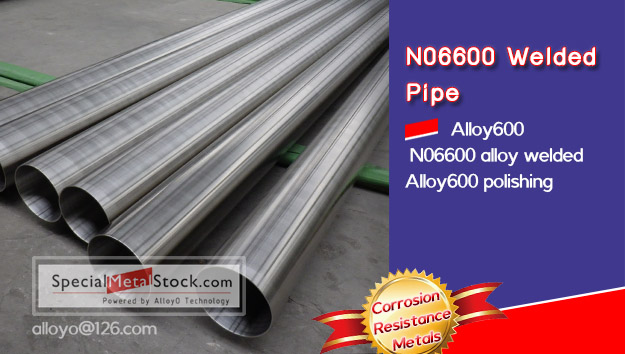

AlloyO: ALLOY600 Welded Pipe Welding, Inspection And Surface Polish Have Finished

According to requirements, Alloy600 N06600 welded pipe not only needs to be tested for welding flaw detection. After the test is passed, the weld seam needs to be repaired afterwards. Polishing of the inner and outer pipe walls is also required.

Compared with small outer diameter welded pipe, alloy600 welded pipe of this batch has a larger outer diameter, and the flatness and mechanical polishing are relatively easy.

In one week, AlloyO Special Metal has basically completed the post-weld inspection and polishing process, and only waits for user to come to spot inspection and then deliver the package.

Alloy600 welded pipe, N06600 alloy welded, alloy600 polishing

What AlloyO can do?

We can Supply Special corrosion resistant alloy imported and original from Germany, US and Japan in stock as below:

--Super Austenitic Stainless Steel

--Duplex Stainless Steel

--Nickel-Based Corrosion Resistant Alloy

--Titanium and Alloy

--RE and its Oxide

Corrosion resistant special metal stock, All in AlloyO.

Details are available at specialmetalstock.com

Compared with small outer diameter welded pipe, alloy600 welded pipe of this batch has a larger outer diameter, and the flatness and mechanical polishing are relatively easy.

In one week, AlloyO Special Metal has basically completed the post-weld inspection and polishing process, and only waits for user to come to spot inspection and then deliver the package.

Alloy600 welded pipe, N06600 alloy welded, alloy600 polishing

What AlloyO can do?

We can Supply Special corrosion resistant alloy imported and original from Germany, US and Japan in stock as below:

--Super Austenitic Stainless Steel

--Duplex Stainless Steel

--Nickel-Based Corrosion Resistant Alloy

--Titanium and Alloy

--RE and its Oxide

Corrosion resistant special metal stock, All in AlloyO.

Details are available at specialmetalstock.com

评论

发表评论